Transporting heavy machinery demands precision, strength, and the right equipment. When you move a scissor lift, you deal with unique challenges that standard utility trailers often fail to address. These machines carry a tremendous amount of weight in a compact footprint, and they possess a high center of gravity that makes stability a top priority. Relying on a generic trailer for this task creates unnecessary risks for your team, your towing vehicle, and the equipment itself.

Investing in a purpose-built trailer changes the entire hauling experience. You gain peace of mind knowing the engineering behind your trailer matches the specific demands of the load. Whether you rent equipment out to job sites or transport your own machinery daily, the right hauling solution transforms a stressful chore into a routine, safe, and efficient process. We’re discussing the various benefits of using a purpose-built scissor lift trailer and how Premier Custom Trailers can help. ’

Enhanced Safety During Loading

Loading a scissor lift onto a trailer presents the most significant safety risk in the transport process. Standard ramps often feature steep inclines that create hazardous conditions for operators. If the machine creates too much torque or loses traction on a steep grade, it can slide or tip, putting the operator in immediate danger.

Purpose-built trailers mitigate this risk through thoughtful design. Manufacturers engineer these units with low approach angles, often using gravity tilt decks or extended, reinforced ramps. This design allows you to drive the lift onto the deck with minimal effort and maximum control. You remove the steep climb from the equation, ensuring the operator maintains full stability throughout the loading procedure.

Superior Weight Distribution Capabilities

Scissor lifts differ significantly from other cargo like landscaping equipment or lumber. They concentrate thousands of pounds into a very small area. A standard utility trailer might possess the overall weight capacity to handle the load, but it may lack the structural integrity to support that weight when concentrated on such a small footprint.

Trailers designed for this specific purpose feature axle placement and frame reinforcement tailored to handle dense loads. This engineering ensures the trailer carries the weight evenly, preventing frame warping or axle damage. You also achieve better tongue weight management, which keeps your tow vehicle level and maintains steering traction on the road.

Reduced Risk of Equipment Damage

Ground clearance poses a constant headache when moving scissor lifts. Many models feature pothole protection bars or battery trays that hang low to the ground. When you attempt to load these machines onto a standard high-deck trailer, you risk bottoming out at the break-over point where the ramp meets the deck.

A specialized trailer solves this geometry problem. By lowering the deck height and smoothing the transition from ramp to bed, the design prevents the undercarriage of the lift from scraping or getting hung up. You avoid costly repairs to the lift’s safety systems and eliminate the frustration of getting a machine stuck halfway onto the trailer.

Optimized Deck Height for Stability

The height of the trailer deck directly influences how the load handles during transport. A scissor lift utility trailer typically rides much lower to the ground than a standard flatbed. This low profile serves a critical function beyond just easier loading; it lowers the overall center of gravity for the entire tow rig.

When you haul a tall machine like a scissor lift, wind resistance and cornering forces act upon it. A lower deck height reduces the leverage these forces have on the trailer. You experience less lean in corners and greater stability at highway speeds. This design feature makes the drive significantly more comfortable and safer for everyone on the road.

Improved Towing Stability on Highways

Trailer sway represents a nightmare scenario for any driver. It often occurs when the load sits incorrectly on the axles or when the trailer suspension cannot dampen the movement of a top-heavy load. Because scissor lifts are inherently top-heavy, they amplify stability issues on improper equipment.

Designers of scissor lift trailers account for this by using suspension systems and axle configurations that resist sway. Torsion axles, often found on these premium trailers, operate independently to absorb road shocks before they transfer to the chassis. You enjoy a smoother ride where the trailer tracks true behind the tow vehicle, reducing driver fatigue on long trips.

Heavy-Duty Construction Features

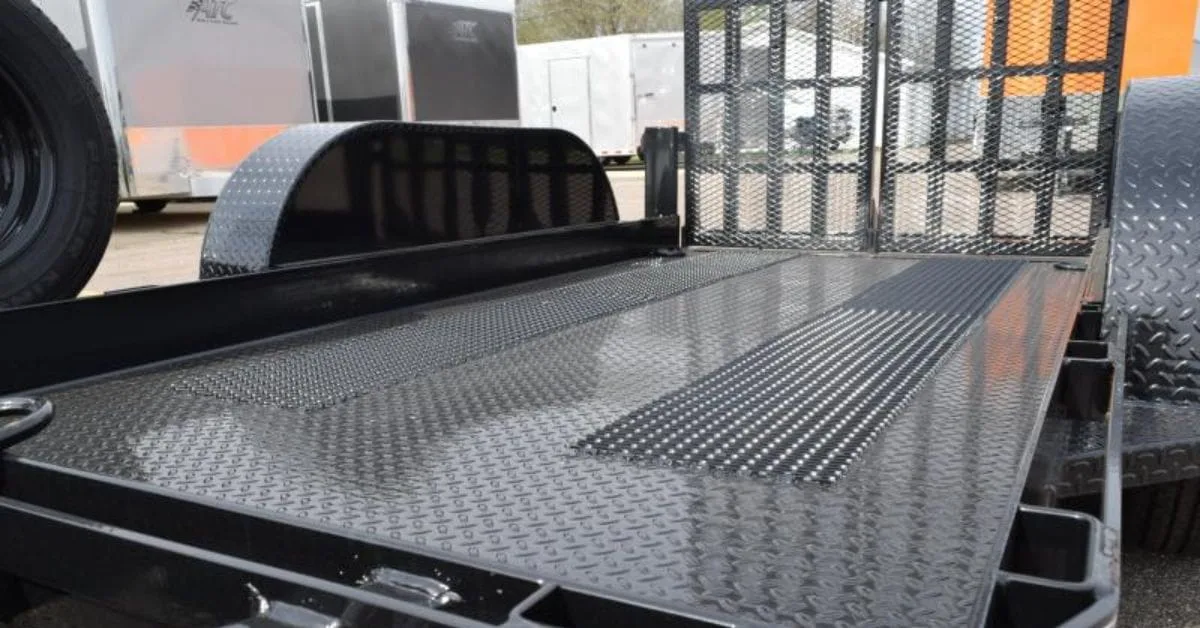

A trailer built for heavy equipment uses materials that far exceed the specifications of a garden trailer. You will typically find thicker steel channels in the frame, reinforced cross-members, and diamond-plate steel flooring rather than wood.

This strong construction withstands the point-loading pressure of solid rubber tires better than wood decking, which can splinter or crack under the weight of a scissor lift. The steel floor also resists damage from oil leaks or battery acid, common occurrences with industrial machinery. You get a piece of equipment that handles daily abuse without compromising its structural integrity.

Compliance With Legal Transportation Standards

Department of Transportation (DOT) regulations regarding heavy equipment transport are strict. Officers look for proper weight ratings, securement methods, and braking systems. Using a trailer that technically fits the lift but lacks the proper Gross Vehicle Weight Rating (GVWR) opens you up to hefty fines and liability issues.

When you purchase a trailer specifically manufactured for this task, you solidify compliance from day one. These trailers often come equipped with the following features:

- Electric brakes on all axles

- Breakaway emergency braking systems

- Proper lighting and reflective tape

- Tires rated for heavy loads

Professional Business Image

Your equipment speaks volumes about your business before you even shake hands with a client. Rolling onto a job site with a straining, undersized trailer and a scissor lift teetering on makeshift ramps looks amateurish and raises safety concerns for site managers.

Arriving with a clean, strong, purpose-built scissor lift trailer demonstrates professionalism and competence. It shows you value safety and invest in the right tools for the job. This perception builds trust with clients, who feel more comfortable hiring a contractor who takes equipment transport seriously. It reinforces your reputation as an industry expert who cuts no corners.

Upgrade Your Hauling Experience

Choosing the right equipment determines the success of your operations. A purpose-built scissor lift trailer offers benefits that go far beyond simple transport. You gain safety, efficiency, legal compliance, and a professional edge that sets you apart.

Evaluate your current hauling methods. If you find yourself struggling with steep ramps, worrying about sway, or constantly repairing your trailer deck, the time to upgrade has arrived. You owe it to your team and your business to invest in a solution that works as hard as you do. Call Premier Custom Trailers at 877-327-0888 to learn more about our trailer solutions.